- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Category

NUP2316

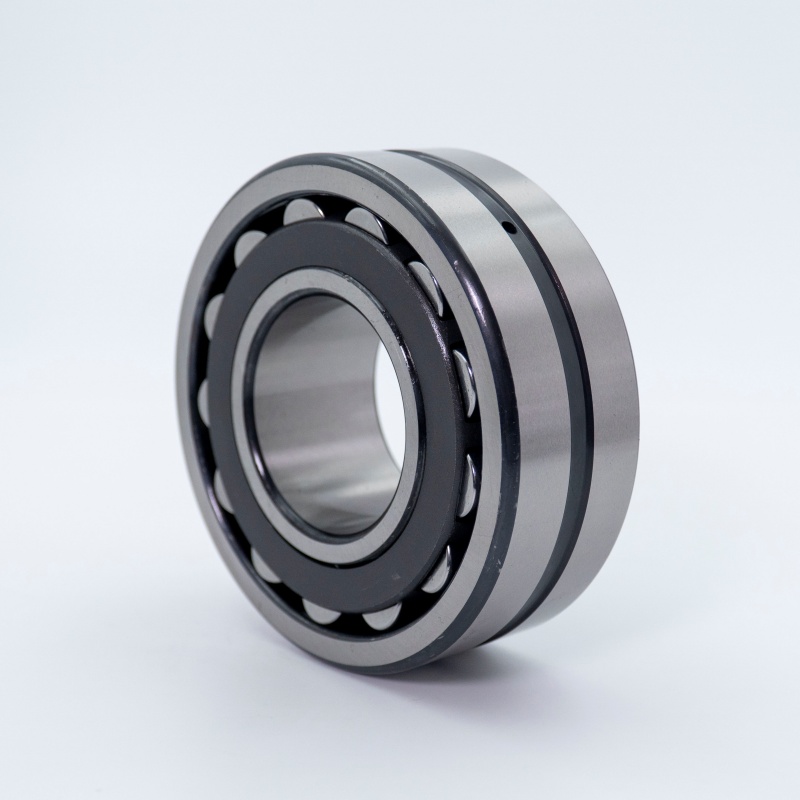

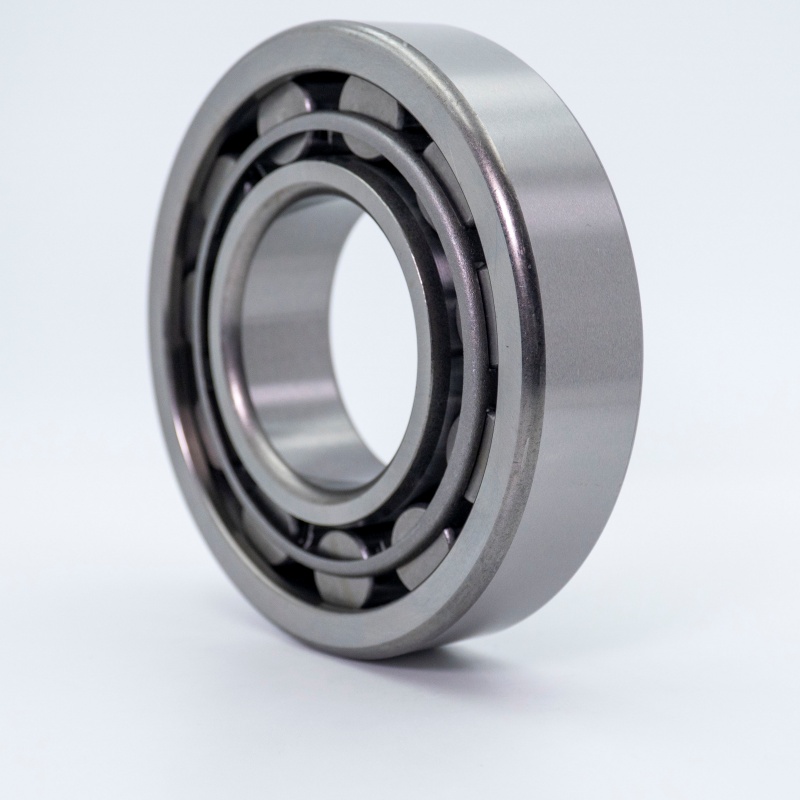

Cylindrical roller bearings are rolling bearings specifically engineered to accommodate high radial loads. Their key rolling elements are cylindrical rollers that make linear contact with the raceways. This design makes them exceptionally effective at handling pure radial forces, serving as critical components in a vast array of industrial applications. Compared to ball bearings of the same size, they offer significantly higher radial load-carrying capacity.

Needle Roller Bearings

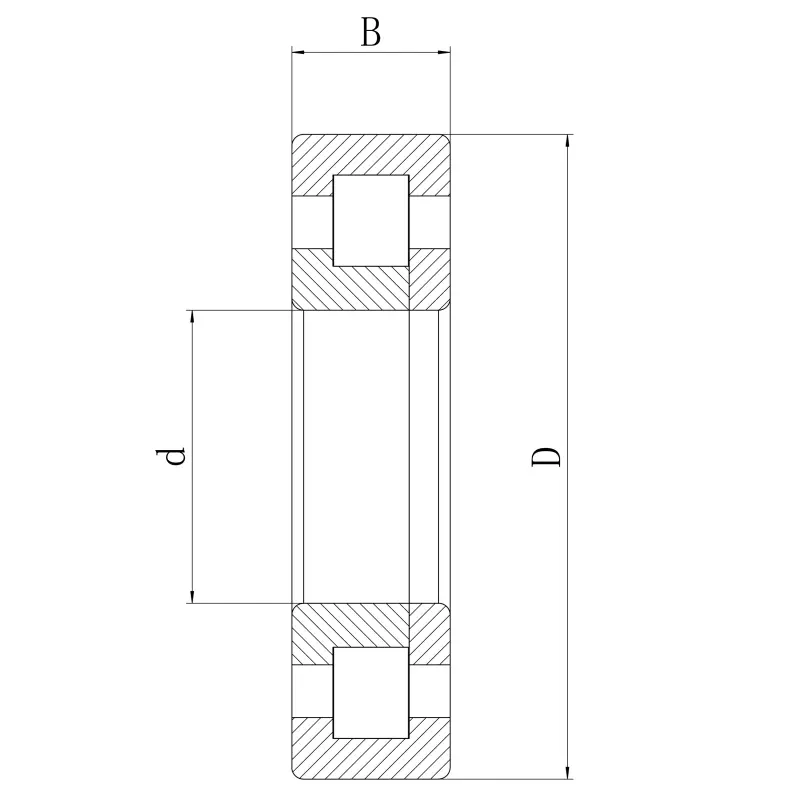

| ISO | NUP2316 | |

| ГОСТ | 92616 | |

| Bore diameter | d | 80 mm |

| Outside diameter | D | 170 mm |

| Width | B | 58 mm |

| Basic dynamic load rating | C | 217 kN |

| Basic static load rating | C0 | 259 kN |

| Reference speed | 2800 r/min | |

| Limiting speed | 1900 r/min | |

| Weight | 6.27 kg | |

Structural Breakdown

Key components include:

- Outer Ring: Typically with raceway (cageless types omit outer ring)

- Needle Rollers: Precision-ground rollers transmitting load via line contact

- Cage: Brass/steel/polymer material spacing rollers (cageless types exclude cage)

- Inner Ring: Optional component (e.g., NA-type with inner ring, RNA-type without)

Classification System

- By Design: Full complement (high load), caged (high-speed capable)

- By Function: Radial, thrust, combination bearings

- Special Types: Flanged (axial positioning), aligning (misalignment compensation)

Technical Advantages

| Feature | Engineering Benefit |

| Ultra-slim section | Saves 60% radial space |

| High load density | 300% higher capacity vs. balls |

| Shock resistance | Line contact distributes stress |

| Rotation accuracy | ±0.03mm for precision systems |

| Note: Speed limitation varies by cage material |

Industry Applications

- Automotive: Transmissions (e.g., JTEKT NK17/20), connecting rods

- Robotics: Articulated joints (full complement type prevalent)

- Aerospace: APU rotor support bearings

- Medical: CT scanner gantry rotation (MRI-safe versions)

- Construction: Hydraulic pump drives (Timken TOR 47)

Environmental Adaptation

| Condition | Recommended Solution |

| High temperature | Ceramic-coated rollers + special cages |

| Corrosive media | Full stainless steel (SS suffix) |

| Contaminated areas | Double-lip contact seals (2RS) |

| Ultra-high speed | Polymer cages + oil-air lubrication |