- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Category

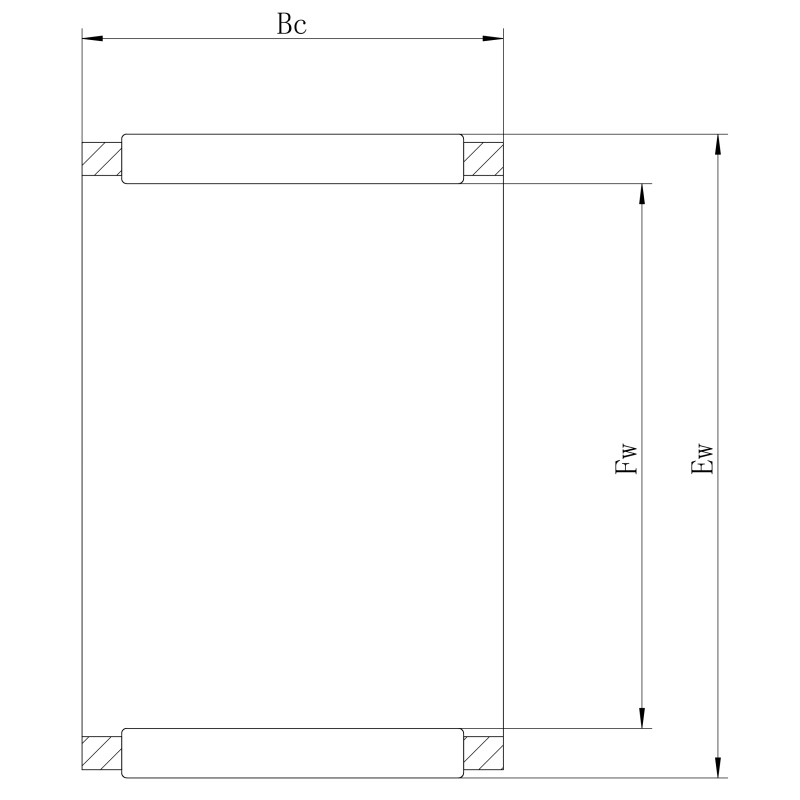

K7X10X8

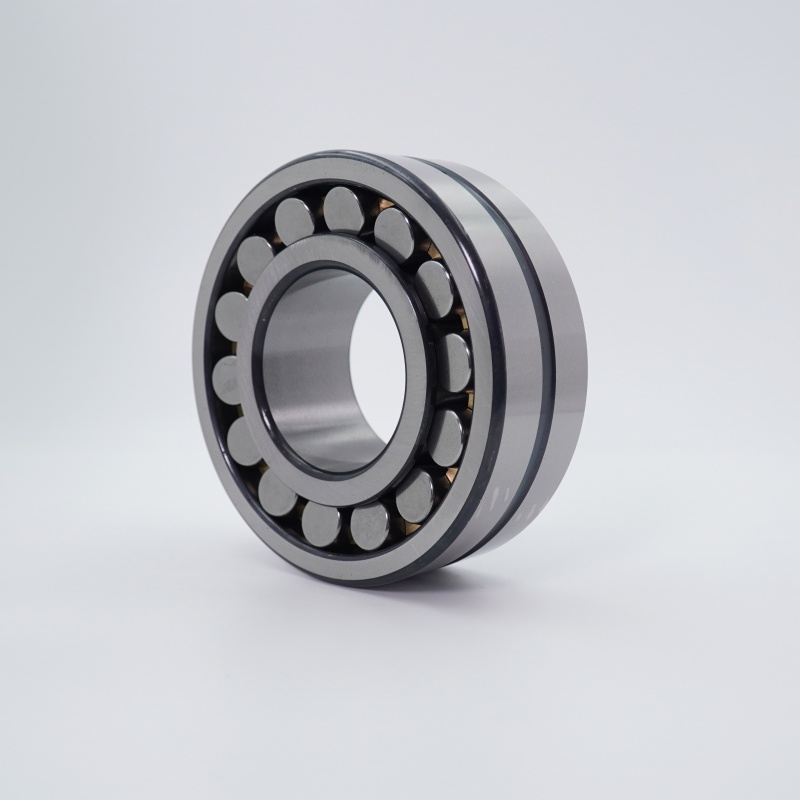

Needle roller bearings utilize cylindrical rollers with a length-to-diameter ratio exceeding 4:1. This “needle-like” geometry enables exceptional radial load capacity within extremely compact cross-sections, providing superior space efficiency compared to ball bearings of equivalent dimensions.

Needle Roller Bearings

| ISO | K7X10X8 | |

| Raceway diameter inner ring | Fw | 7 mm |

| Outside diameter | Ew | 10 mm |

| Width | Bc | 8 mm |

| Basic dynamic load rating | C | 1.37 kN |

| Basic static load rating | C0 | 1.27 kN |

| Limiting speed | 16300 r/min | |

| Mass bearing | 0.0017 kg | |

Structural Breakdown

Key components include:

- Outer Ring: Typically with raceway (cageless types omit outer ring)

- Needle Rollers: Precision-ground rollers transmitting load via line contact

- Cage: Brass/steel/polymer material spacing rollers (cageless types exclude cage)

- Inner Ring: Optional component (e.g., NA-type with inner ring, RNA-type without)

Classification System

- By Design: Full complement (high load), caged (high-speed capable)

- By Function: Radial, thrust, combination bearings

- Special Types: Flanged (axial positioning), aligning (misalignment compensation)

Technical Advantages

| Feature | Engineering Benefit |

| Ultra-slim section | Saves 60% radial space |

| High load density | 300% higher capacity vs. balls |

| Shock resistance | Line contact distributes stress |

| Rotation accuracy | ±0.03mm for precision systems |

| Note: Speed limitation varies by cage material |

Industry Applications

- Automotive: Transmissions (e.g., JTEKT NK17/20), connecting rods

- Robotics: Articulated joints (full complement type prevalent)

- Aerospace: APU rotor support bearings

- Medical: CT scanner gantry rotation (MRI-safe versions)

- Construction: Hydraulic pump drives (Timken TOR 47)

Environmental Adaptation

| Condition | Recommended Solution |

| High temperature | Ceramic-coated rollers + special cages |

| Corrosive media | Full stainless steel (SS suffix) |

| Contaminated areas | Double-lip contact seals (2RS) |

| Ultra-high speed | Polymer cages + oil-air lubrication |